Precision and automation in micro waterjet cutting

WatAJet – an Italian excellence in micro waterjet cutting – has transformed an academia-developed technology into a unique production process. Thanks to Mitutoyo's Quick Vision Apex, the company has revolutionised its quality control, taking precision, automation and reliability to the next level.

Specialising in micro waterjet cutting, WatAJet is one of the finest examples of Italian manufacturing excellence; it stands out for its ability to combine cutting-edge technology and extreme precision, while processing materials that would otherwise be impossible to handle without compromising quality. Founded as a spin-off of the Politecnico di Milano, the company has been able to transform an academia-developed technology into a distinctive industrial competence: WatAJet is presently the only company in Italy and one of the very few in Europe to use this revolutionary cutting technology on a production scale.

“Given the very tight tolerances we are used to working with, compromises are not acceptable,” says Francesco Arleo, Head of R&D at WatAJet. “We needed a tool that was precise, flexible and reliable over time. Mitutoyo's Quick Vision Apex was a real game changer.”

WatAJet operates in a specialised production niche. With water jets measuring 0.2 mm in diameter, high pressures and ultra-fine abrasives, the company is able to cut extremely hard or extremely delicate materials without altering them. Special steels, titanium, ceramics, multilayer composite materials, engineering plastics and glass are just some of the materials that WatAJet can process, guaranteeing exceptionally tight tolerances on even very small parts. Sectors such as biomedical, aerospace and scientific research require faultless components, as the slightest imperfection can compromise the entire product.

Micro waterjet cutting is a unique technology. Unlike laser or electroerosion, it does not thermally alter the material and allows any surface to be processed, even composites or layered materials with different mechanical characteristics. “We cut materials that are impossible for others,” explains Mr. Arleo. “In some cases, a tolerance of two microns is required on thicknesses of half a millimetre. And everything must be repeatable.” Each component requires care not only in terms of dimensions but also aesthetics, because many parts intended for biomedical use must be flawless both technically and visually.

It is not only a technical challenge, but also a manufacturing one. An increasing number of customers wish for WatAJet to provide full control of the parts, a request that would traditionally involve hours of manual work or the use of multiple measuring instruments. For a company that works with high-precision microcomponents, it could have been a significant limitation, which has, however, been overcome thanks to the introduction of Mitutoyo's Quick Vision Apex.

Mitutoyo's machine has revolutionised quality control management. The main advantage is the ability to combine three technologies in a single system. High-resolution optical vision allows two-dimensional components and micro-profiles to be measured; the contact probe allows three-dimensional elements or cylindrical surfaces to be measured; the laser acquires profiles and height measurements with extremely high precision. All within a single, fully programmable cycle, just like a numerically controlled machine tool.

“With three technologies in a single machine, we can measure any part that comes out of production,” explains Mr. Arleo. “If we hadn't chosen the Quick Vision Apex, we would have had to purchase three different instruments. Here, everything is integrated and can be automated.” The ability to program complete measurement cycles and let the machine operate autonomously has allowed WatAJet to manage even very large batches while maintaining consistent precision and ensuring full data traceability.

Every day, Quick Vision Apex starts up at the beginning of the shift and works for hours without interruption. It is no longer just a measuring tool: it has become an integral part of the production flow. Automatically generated reports, structured management of measurement cycles, and the ability to repeat complex checks without errors make metrology an ally of production, rather than a separate and potentially critical step. This level of automation has enabled WatAJet to satisfy customers with stringent requirements, comply with complex control plans, and focus on its technological growth by reducing repetitive manual tasks.

Quick Vision Apex has also paved the way for machining and checks that were once very difficult to manage. Particularly complex three-dimensional components, deep micro-holes, intricate profiles on extremely hard materials: everything can be measured with precision and repeatability. “It has become a production machine, not just a measuring tool,” emphasises Mr. Arleo. “Program it once, it does the rest. And it is always accurate.” For a company like WatAJet, where quality is central to its offering, such reliability is an indispensable asset.

Reliability is a recurring theme when Mr. Arleo talks about Mitutoyo. Even manual instruments — calipers, micrometers and small tools — are part of everyday life at the company and help to consolidate its reputation for precision. “A cheap caliper may cost less, but after six months it is no longer able to measure accurately. Mitutoyo's small tools last for years, and the measurement is always reliable,” he says. Consistent performance thus becomes a strategic element for a company operating in regulated sectors, where error is not tolerated.

However, the collaboration with Mitutoyo is not limited to technology. It is also a matter of human relations, listening and mutual trust. “The added value is knowing that if you call, there is always someone ready to help you. That's what we look for in a technology partner,” explains Mr. Arleo. The relationship between WatAJet and Mitutoyo is a partnership built over time, based on constant availability and support, which is essential for a company that works on extremely complex components.

Thanks to Quick Vision Apex, WatAJet is now able to guarantee 100% dimensional checks even on complex batches, to significantly reduce measurement times, to increase process repeatability and tackle difficult parts with the confidence of a system that never fails. The machine has made it possible to scale up production without compromising quality, allowing the company to grow while remaining focused on high value-added machining.

“Mitutoyo is not just a supplier to us. It is a cornerstone,” says Mr. Arleo. And Quick Vision Apex is not just a machine that measures parts: it is the tool that allows WatAJet to transform precision, reliability and automation into a real competitive advantage. “Every day, we know that it will do exactly what it is supposed to do, with no surprises,” concludes Mr. Arleo. “And that's what allows us to maintain the highest standards without slowing down production.”

Images:

1. At its headquarters in the province of Varese, WatAjet performs high-precision machining to manufacture parts of various geometries, from prototypes to initial pre-series, up to batches of thousands and tens of thousands of pieces.

2. Mitutoyo's Quick Vision Apex measuring machine has revolutionised WatAjet's quality control management and is an integral part of the company's entire production cycle.

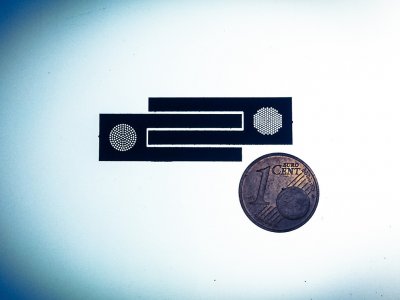

3. Using water jets with a diameter of 0.2 mm, high pressures and very fine abrasives, the company is able to cut extremely hard or delicate materials without altering them.

4. The versatility and flexibility of Micro Abrasive Waterjet technology allow for extremely accurate processing of any material, metallic or non-metallic, in thicknesses ranging from a tenth of a millimetre to a few tens of millimetres, without introducing any thermal alteration.

5. Mitutoyo's hand tools — calipers, micrometers and small tools — are also part of everyday life at WatAJet and help to consolidate its reputation for precision.

About Mitutoyo Corporation

Mitutoyo Corporation is a world leader in precision measuring technology, offering a comprehensive range of metrology products and solutions. Founded in 1934 and headquartered in Kawasaki, Japan, Mitutoyo has grown into a global company with a presence in over 40 countries. Its extensive product portfolio includes micrometers, calipers, dial indicators, coordinate measuring machines (CMMs), vision systems, form measuring equipment, and advanced metrology software.

With a commitment to accuracy, quality, and innovation, Mitutoyo serves a wide range of industries including automotive, aerospace, electronics, medical, and manufacturing. The company also operates a network of accredited calibration laboratories, training centers, and technical support hubs, helping customers maintain the highest standards in quality assurance and production efficiency.

Mitutoyo’s philosophy, “Good environment, good people, good technique”, drives its mission to support global industry through precise measurement and continuous technological advancement.

Mitutoyo Europe GmbH

Regional Marketing Division

Borsigstraße 8-10

41469 Neuss

GERMANY

Schertz Pauline

Phone : +39 3425736398

p.schertz@mitutoyo.eu

Editor Details

-

Company:

- Mitutoyo Europe GmbH

-

Name:

- Schertz Pauline

- Email:

-

Telephone:

- +393425736398

- Website: